At Brand Felt Group, we like challenges. That’s where innovation begins.

Whether you’re looking for a custom product, new solutions to a current problem, or added features to an existing product, we’re here to help you.

Being vertically integrated has given us a deep understanding of our materials and how to achieve consistent quality every time. Our cutting and converting departments allow us to prototype ideas and build according to your exact needs. To achieve this, we work with a diverse set of materials:

Complete converting solutions

Our facilities are equipped with precision machinery, offering an extensive range of capabilities, and the flexibility to handle orders of all sizes. Alongside our standard equipment, we also build custom machines for special needs.

80% of our customers choose customized products. If you need a service not listed here, get in touch – we're here to help. You can also learn more about our capabilities here.

With high-speed rotary presses, we can die-cut materials without damaging the adhesive backs.

Our CAD/CAM office with 3D capabilities and digitizer allows us to convert your sketch to a 2D or 3D drawing.

Ideal for materials sensitive to heat or for cutting materials such as high density felt, foam etc.

We offer laser etching and engraving services. Depending on the material density and surface, we can offer this service for foams, felts, and cork.

We can slit most master rolls of felt, foam, and cork into strips for you starting at 1/8” width.

We offer a range of adhesive options depending on your application, including 3M adhesive. Our PSA backing can be applied to a wide variety of our products.

With your choice of PSA (pressure-sensitive adhesive) or HSA (heat-sensitive adhesive), we offer laminating services for rolls, sheets, and die cut pieces.

Our sewing department is equipped with over 40 machines capable of sewing felt, leather, neoprene, and more.

Our Process

Define Your Needs

We start by understanding whether you have a specific requirement or need our expertise to develop the right solution.

Gather Details

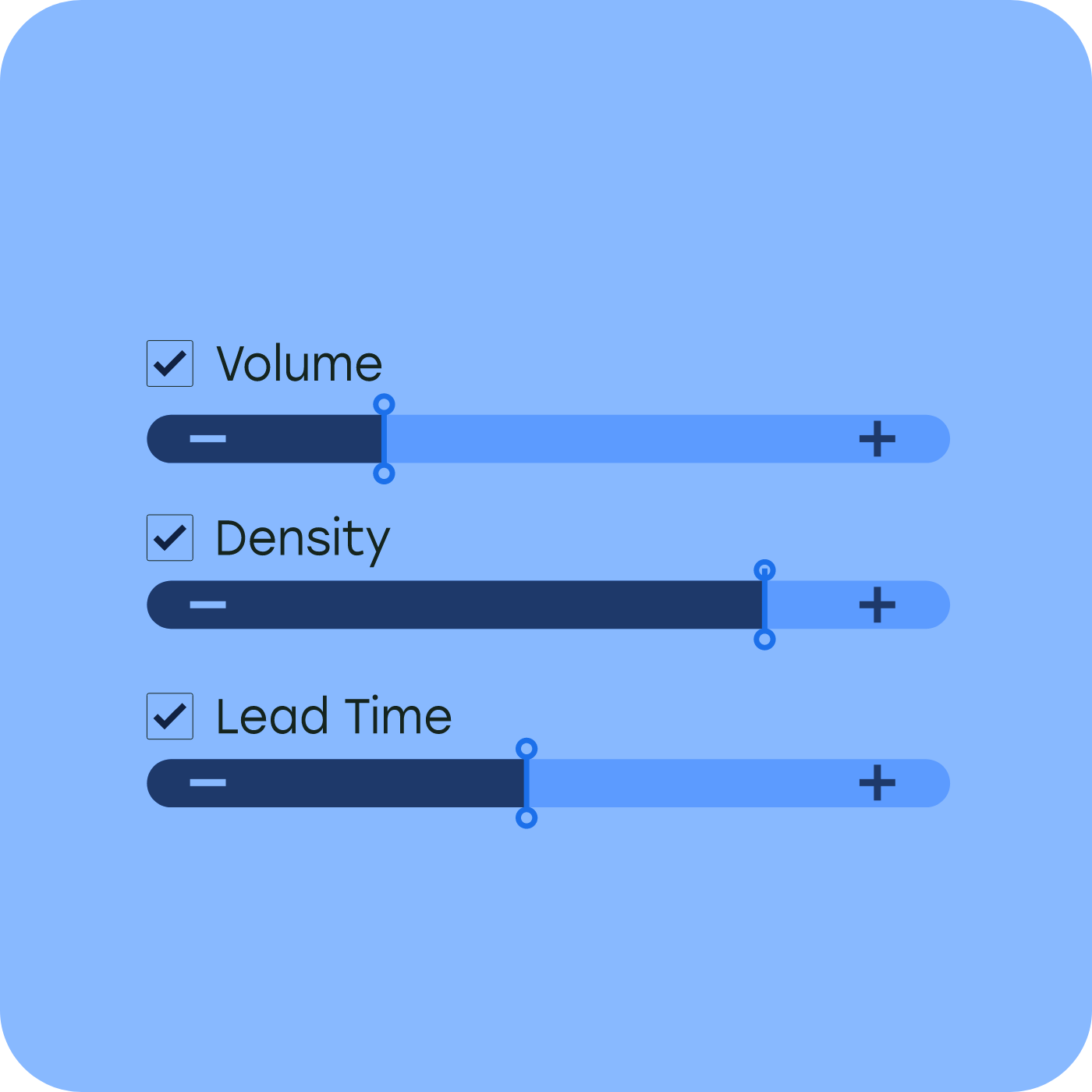

We analyze your request and collect key information such as volume, lead time, and other requirements.

Material Selection

We provide material samples so you can finalize the best choice for your application.

Prototype

We create a prototype and refine it until it perfectly fits your needs.

See our product development in action!

Featured in Bloomberg TV’s show “World’s Greatest” is our customer Vic Firth!

Vic Firth is a leading manufacturer of musical instruments. They use our custom felt marching mallet heads. We developed these for precise tone and consistent sound.

Cork + Cling Foam Pads

In the windows and glass industry, a significant amount of glass breakage happens during transportation and storage. If not handled properly, stacked glass can crack under its own weight, and any sudden movement increases the risk of shattering. A common workaround has been to tape padding directly onto the glass, but this often leaves adhesive marks and stains.

Cork cling foam pads offer a cleaner, more effective solution. Made by our brand Combi-Fab, these specialty pads are produced by laminating fine-grain cork to cling foam - a closed-cell PVC foam. The cork layer provides a smooth, durable surface with insulation and pressure resistance, while the cling foam allows the pad to temporarily adhere to glass, steel, and some plastics without the use of adhesive.