At the heart of our craft lies a deep understanding of felt – the fiber, the composition, and the manufacturing method. We can create custom felts that meet the specific applications you’re looking for.

We work with an extensive range of fibers

Felt is produced using natural fibers such as wool, man-made fibers like polyester and polypropylene, or a combination of both. Wool provides inherent elasticity, insulation, and moisture-wicking properties, while synthetic fibers contribute enhanced tensile strength, dimensional stability, and cost-efficiency.

Blended felts leverage the advantages of each, offering tailored performance for a broad range of industrial and technical applications. We work with a wide range of fibers to suit different performance needs, including:

We provide engineered solutions

We can achieve your desired characteristic. Each fiber brings unique properties to the blend, allowing us to manipulate the material for different applications.

Explore the customizable properties of felt and learn how we can adapt them to meet your needs.

Felt can be made in a variety of densities - from rock-hard to pillow-soft. This depends on fiber content, manufacturing method, and finishing treatment.

Felt can range from soft to coarse, depending on fiber content, manufacturing method, and finishing process.

Felt can be left in its natural tones - ranging from gray to off-white with slight batch variations. It can also be dyed in a wide range of colors. Dye absorption varies by fiber type, affecting color consistency and vibrancy.

Felt can be engineered for thermal insulation and sound absorption by adjusting fiber content, density, and thickness.

Felt can be customized for different tolerances, offering excellent compression and natural elasticity for quick recovery.

Felt can be engineered to withstand high-heat environments, with performance largely determined by fiber content, density, thickness, and finishing treatments.

Felt can be engineered to either repel water or wick and absorb liquids. This is influenced by fiber content and density.

"It’s like crafting a recipe, custom blends let you choose the right mix of fibers to reach the perfect performance."

- Jack Brand, President & CEO of Brand Felt Group

Want to see our custom felts in action?

Featured in Bloomberg TV’s show “World’s Greatest” is our customer Yurta!

Yurta is a Canadian company pioneering the yurt industry. They use our custom blended needle punch felt with a reflective backing. This keeps the interiors warm in the winter, and cool in the summer.

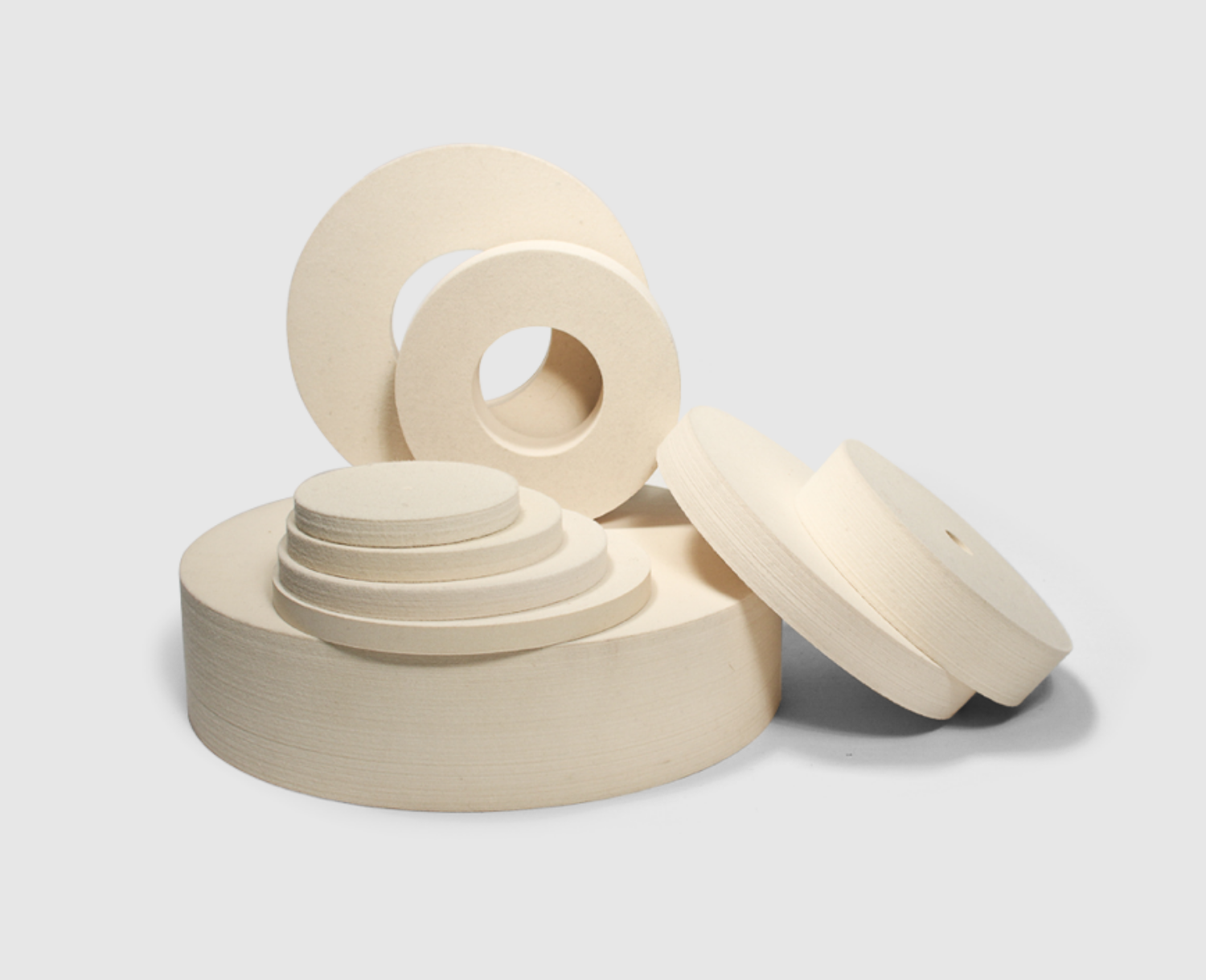

Polishing Wheels for Glass

In the windows and glass industry, polishing wheels are used on glass bevels and are regularly exposed to cerium oxide and water. Because the bevel is grounded down and then polished multiple times, the wheels must maintain their shape. If a wheel swells in water, it can lead to inconsistent polishing and even increase the risk of the glass breaking due to changes in pressure.

Brand Felt Group has developed a polishing wheel made from 100% wool felt that maintains its density and resists swelling in water, ensuring consistent, reliable results every time.

View all case studies